America’s space industry seems mature, but the supply chain that provides all the parts and components for rockets, satellites, and other spacecraft is considerably less so. Gimbal Space is aiming to change that, starting with components in the crucial subsystem that enables a spacecraft to orient itself in space — but delivered cheaper and a whole lot faster.

The startup was founded by Dhaval Shiyani, a mechanical engineer who has made a career of scaling complex hardware systems. He joined Tesla in 2017 and helped grow the company’s Fremont factory output of Model 3 vehicles from 50 to 5,000 per week over a span of six months. After that, he moved on to Ethicon, a Johnson & Johnson subsidiary, designing high-volume medical devices. There, the challenge was ensuring each component was manufactured and tested to be 100% reliable — and to do that across a million components.

“I learned a lot of high-volume manufacturing, what it takes to build a company rapidly and what it takes to scale it,” he said of his time at Tesla.

Shiyani found his way into the space ecosystem when he joined the electric propulsion startup Apollo Fusion. CEO Mike Cassidy brought him on to take the prototype thruster from the lab to production. That meant reducing part count and lowering costs, even if that involved bringing the design of a component in-house. The startup was eventually acquired by Astra, and there Shiyani was pulled onto the team that was in the early stages of designing a 13,000-satellite constellation. He eventually moved to Earth imaging company Planet, where he worked on their next-gen imaging satellite, Pelican.

Throughout his time in the space industry, he says he repeatedly encountered the same pain points when it came to parts ordering: high cost, extremely long lead times, and an overall immaturity in the supply chain, where many components were not yet commoditized. This is an issue of “focus, inertia, and approach” in legacy suppliers, he says.

“There is a need and a demand that has not been satisfied through the existing providers,” he explained. “These components, these subsystems, are almost always secondary revenue streams. They can pretty much charge extremely high premiums on some of these components because they can most likely get away with it. It’s [an] extremely lucrative, high-margin product line that they have no incentive to either deliver fast or deliver cheaply.”

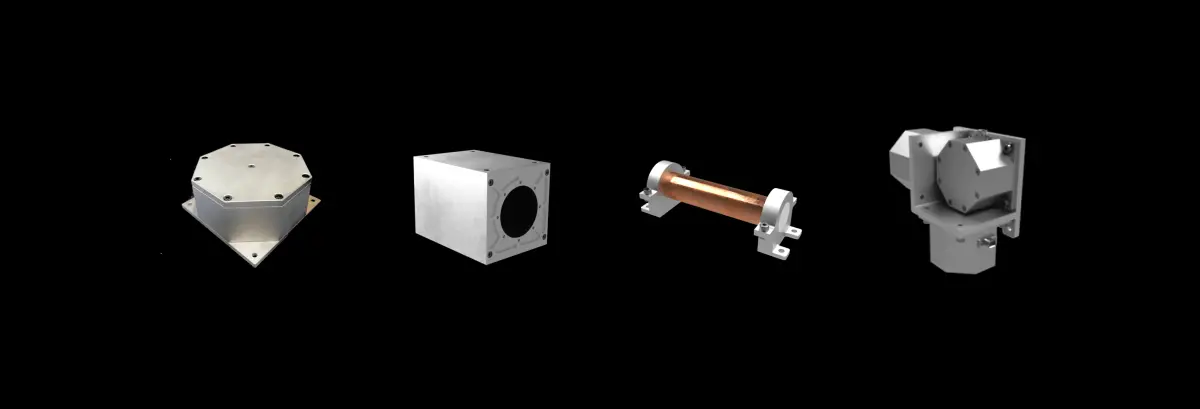

The subsystem Gimbal is targeting first is called the attitude determination and control system or ADCS, a device that demands extreme precision and includes components like star trackers, reaction wheels and torque rods. Gimbal also plans to eventually expand to other components of ADCS, like magnetometers, sun sensors, and rate sensors.

There are a couple of major ADCS component suppliers in North America, including Honeywell, Blue Canyon Technologies (which is owned by RTX), and Rocket Lab, through its acquisition of Canada-based Sinclair Interplanetary. Some suppliers specialize in large components, while others go very small, making it a fairly fragmented market. (Shiyani’s comments were not about any supplier in particular.)

Generally, suppliers are not interested in or incentivized to lower prices to compete with other companies, Shiyani said: “There isn’t a lot of leeway there. Obviously, as you scale up, you can get some favorable treatment, but it’s not anywhere close to, ‘If I’m getting it for this much from X, then like you should lower your prices.’”

Lead times are also very slow: months if not years, far beyond the possibility for startups that are concerned about monthly burn and cost. In contrast, Gimbal is aiming to deliver things in half the time, with prices that are 25-30% lower than legacy suppliers. One way the company wants to bring such drastic reductions to the supply chain is by moving some of the manufacturing to India.

The company has already identified a manufacturing partner in India that can rapidly deliver reliable hardware; Gimbal has a director in India helping to oversee that effort. In the short term, Gimbal will be contract manufacturing in both India and the U.S., though the goal is to build out its own manufacturing capabilities.

The company has raised $1.2 million led by Abu Dhabi-based AUM Ventures with participation from Shakti VC, Z21 Ventures, and others. That money will go toward getting Gimbal’s components in orbit for the first time — whether that’s on a customer spacecraft or on a demo flight just to demonstrate the functionality — growing the team, and building out manufacturing. The startup is currently aiming to have the components ready by the end of the year, with the first flight occurring within a few months after that.